Application of Fumed Alumina 100 in Energy Efficient Lamps

With the growing desire to minimize carbon footprint and improve energy efficiency, the world switched to more sustainable lighting solutions in recent years. Following the green trends, the governments put great efforts to promote the use of modernized fluorescent lamps and encourage the industrial development of fixtures with higher luminous efficiency and longer life span. Along with the gradual elimination of standard iridescent bulbs, the traditional fluorescent lamps have been transitioning as well. Characteristics such as fine particles, high purity, good dispersibility, and positive surface charge opened the path to the application of Fumed alumina 100 in energy-efficient lamps as a reinforcer of tomorrow.

What Are Energy Efficient Fluorescent Lamps?

Fluorescent lamps are a type of energy-efficient lamp that uses less power than traditional incandescent light bulbs. Fluorescent lamps work by passing an electric current through a gas-filled tube. This causes the gas to glow, and the light is then emitted from the tubes.

There are a number of different types of fluorescent lamps, including:

- Compact fluorescent lamps (CFLs)

- Linear fluorescent lamps

- High-intensity discharge lamps (HIDs)

Each of these types of lamps has its own unique benefits and drawbacks. For illustration, CFLs are more efficient than traditional incandescent light bulbs but also slightly less bright.

Advantages of Using Fumed Alumina 100 in Energy Efficient Lamps

Commonly used straight tube fluorescent lamps, as well as glass tube bend compact fluorescent lamps, have some drawbacks. Phosphor and the glass surface adhesion are imperfect, typically requiring the addition of high-purity, nanoscale particles for reinforcement.

The fumed alumina in energy-efficient lamps is widely used as a lighting phosphor reinforcement. Due to its high purity, the absorption of ultraviolet and visible light is minimal, while the visible light emission of the lamp remains unaffected. The particle size of fumed alumina aggregates is 0.1~0.2 μm; therefore, it can be used as the filler powder of phosphor with a particle size of 6~10 μm. The addition of 2%~5% fumed alumina as an inorganic binder in phosphor slurry provides a positive charge on its surface, counteracting the negative charge of phosphor and glass. That way, fumed alumina enhances the bonding force between phosphor and lamp, eliminating the risk of phosphor falling off.

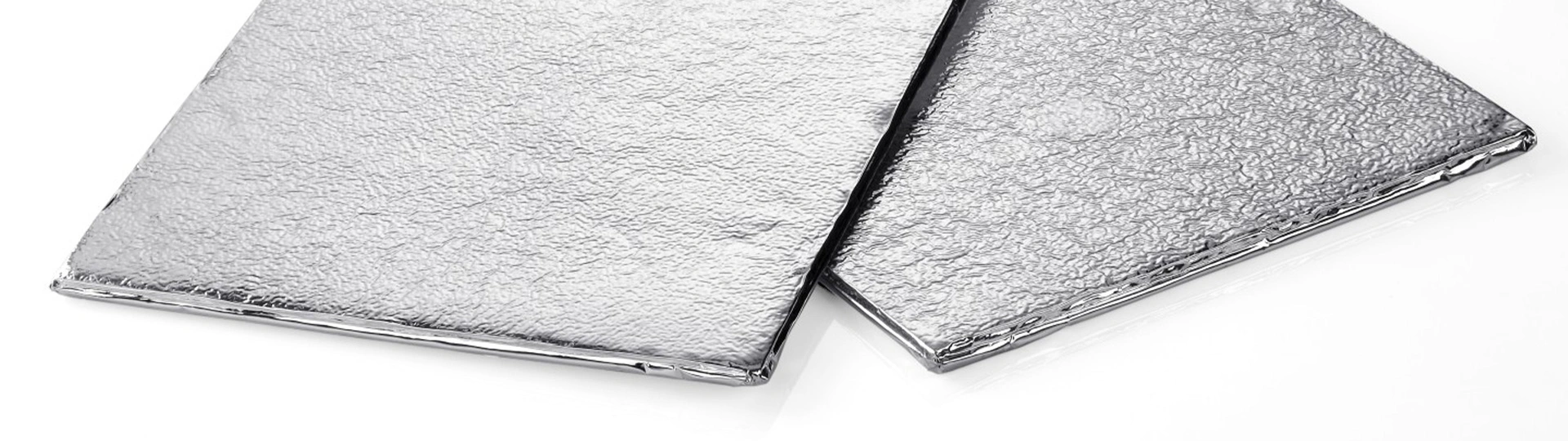

In addition, fumed alumina’s fine particles will also fill in the phosphor coating of the vacancy, making the layer smooth and flat. The result is a uniform luminescence, but also – to a certain extent – prevented penetration of mercury into the glass and sodium. Deterring penetration from the inner surface of the glass tube to the phosphor powder layer of thermal diffusion means slowing down the blackening process of the glass tube. Without the generation of black sodium amalgam on the phosphor layer, the light decay of the lamp is reduced.

In addition, due to the opaque white appearance of Fumed Alumina 100, light scattering occurs when the rays hit its surface. The light-scattering properties, as well as the native particle size and aggregate structure, make fumed alumina a near-perfect optical medium, i.e., a wavelength-selective UV-reflective material.

Fumed Alumina 100 in Energy Efficient Lamps Is More Than Enhancer

- Fine particle size: With the native particle size of 7nm~40nm, fumed alumina 100 has excellent dispersibility and good optical properties.

- High purity: fumed alumina 100 has an ultra-high purity of 99.99%. In addition, it does not contain metal ions or other harmful impurities, so it can ensure the quality of the products.

- Good adhesion: Fumed alumina 100 has a positive surface charge, so it can firmly attach to the substrate and improve the adhesion of the coating.

- Excellent hiding power: With good hiding power, fumed alumina 100 can effectively cover the substrates and improve the color saturation of the coating.

Low price: Fumed alumina 100 is a low-cost nanomaterial with high performance. It can save costs in many applications.

How Can Fumed Alumina 100 Application Improve the Performance of Energy Efficient Lamps

The scattering factor of fumed alumina at various wavelengths in the visible range does not differ much, but the scattering factor rises sharply in the UV region. According to the available data, the scattering intensity of light at 254 nm is 16 times higher than that at 500 nm (green light) and 30 times higher than that at 800 nm (red light) under the same circumstances. Therefore, the inner side of the fluorescent tube alumina protective film for visible light is nearly transparent but will reflect the ultraviolet light through the phosphor layer, continuing to excite the phosphor light, thereby improving the luminous efficiency of fluorescent lamps.

Lamps without the application of Fumed Alumina 100 have mercury continually diffused through the layer of fluorescent material into the glass tube. As a result, the formation of sodium amalgam occurs, and the lamp gradually turns gray over time. On the one hand, this effect provokes the loss of UV-generating mercury. On the other hand, the gray lamp will absorb more visible light to convert it into heat, resulting in reduced luminous efficiency.

To compensate for these losses, mercury amount, as well as power, must be increased – consequently making the lamp hotter. The heat further aggravates the spread of mercury and creates environmental stress problems. If a layer of Fumed Alumina 100 is coated on the inside of the lamp as an effective mercury barrier, the amount of toxic heavy metals can be significantly reduced. Simultaneously, the lamp’s luminous efficiency will increase, along with its projected life span. This design is commonly used by some famous international manufacturers to produce high-quality fluorescent lamps.

If you have any questions about CE Chemicals Fumed silica, or if you would like to request a sample, please contact us. Our experts will be happy to assist you.