Going Green: Fumed Alumina & Silica Application in Vacuum Insulation Board

The necessity to continually improve energy efficiency in all industry segments reflects strongly to thermal insulation standards, requiring innovations. With the development of science and technology and the expansion of downstream application fields, inorganic nano-materials showcase an unlimited potential in the industry application prospect. As a result, fumed alumina and fumed silica application in the vacuum insulation board (VIP) production proved that both materials have a future in the “green” field.

In this article, we will explore and discuss the benefits of each compound and their mutual impact on sustainable development.

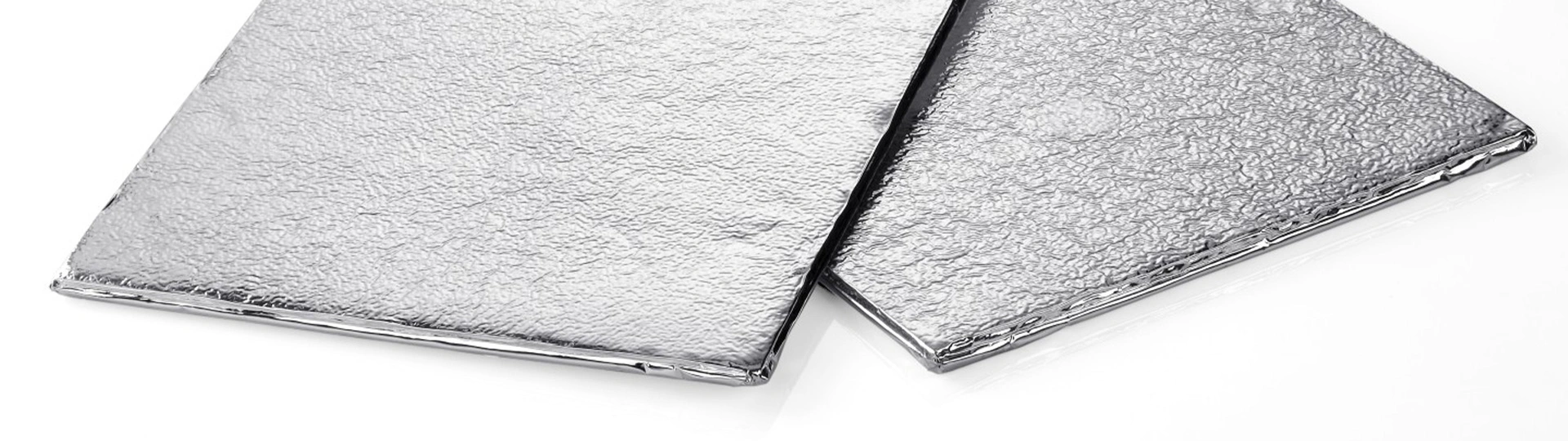

What Is Vacuum Insulation Board (VIP Board)

A vacuum insulation panel is an insulating material comprising a rigid core with a vacuum-sealed cavity used for thermal insulation. VIP board is a type of vacuum insulation panel composed of multiple layers of Fused Quartz and Fumed Alumina bonded together with a resin. The resulting product has excellent thermal insulation properties, as well as high mechanical strength.

Vacuum insulation boards are an increasingly popular alternative to traditional materials such as fiberglass and cellulose. It can effectively avoid the heat transfer caused by air convection. In return, the thermal conductivity can be significantly reduced to less than 0.035w/(㎡.k).

The main advantage of the VIP board is its ability to provide excellent thermal insulation with a very low thickness, making it an ideal material for use in applications where space is limited. VIP boards can be utilized in a wide range of industries, including construction, automotive, and electronics. At present, it is mainly found in household refrigerators, yacht refrigerators, mini-refrigerators, car refrigerators, deep-freezers, electric water heaters, vending machines, freezer boxes, refrigerated containers, as well as in building wall insulation and LNG storage and transportation solutions. It is also popular among homeowners for use in attics and crawlspaces.

VIP board is a more efficient way to insulate the space while lowering carbon footprint as well as energy bills. In addition, the absence of harmful chemicals or fibers makes it quite an environmentally friendly solution. Its eco-friendly composition, together with high efficiency, makes it one of the most advanced thermal insulation panels in the world.

Advantages of Fumed Alumina & Fumed Silica Application in Vacuum Insulation Board (VIP board)

A vacuum insulation board is generally composed of three parts: core material, diaphragm, and air-absorbing agent (desiccant). The selection of core material is the key factor to determine its performance.

There are many choices of vacuum insulation board core materials, such as glass wool, micro-silica powder, aerogel, pyrogenic silica, fumed silica, and fumed alumina. At present, due to the limitation of cost and technology, glass wool and micro silica powder are commonly used as core materials. However, that comes with disadvantages such as short service life, unstable production quality, and severe heat loss of sealing edge.

On the other hand, fumed silica and fumed alumina, as nano-materials with a range of unique characteristics, make a very suitable alternative for the core material of vacuum insulation boards.

Fumed alumina is a white, powdery substance produced by the vaporization of aluminum oxide. Fumed silica is created by the vaporization of silicon dioxide. Both materials are extremely lightweight with a high thermal insulation value. Fumed alumina is also very strong, making it an ideal material for VIB production. While fumed silica is slightly less rigid, its thermal insulation value and tensile strength are higher than fumed alumina’s.

The thermal conductivity of air is 0.022 watts per meter per kelvin, while the thermal conductivity of vacuum is 0.000017 watts per meter per kelvin. This means that the inclusion of fumed alumina and fumed silica in a VIB product can reduce the thermal conductivity of the product by up to 99.8%. As a result, combined fumed alumina and fumed silica application in VIB products results in superior insulation properties.

In addition to their high thermal insulation value, fumed alumina and fumed silica also improve the strength of VIB products making them less likely to break or collapse under pressure.

An Example of Fumed Silica Application In VIP Boards

We’ll make her an example of a Fumed silica application. Firstly, it is an ultra-fine nano-material, a native particle size with a high specific surface area. It can reach 400㎡/g, so its aggregates and the voids inside the particles are very small while the porosity is relatively high. Secondly, the shape of fumed silica is conditioned by the fusion of the native particles of silica, making three-dimensional dendritic silica aggregates, and then by hydrogen bonding and van der Waals force.

The fumed silica is prepared at high temperatures (1200-2100℃), so it has a naturally high heat resistance property. Finally, the molding process is relatively simple: The compound can be directly mixed with other additives, such as infrared masking agents, bonding agents, and reinforcing agents, and then molded.

In short, compared to core filling materials such as aerogel, fumed silica has obvious advantages in terms of production cost, production efficiency, electrical properties, thermal stability, and service life alone.

If you have any questions about CE Chemicals Fumed silica, or if you would like to request a sample, please contact us. Our experts will be happy to assist you.