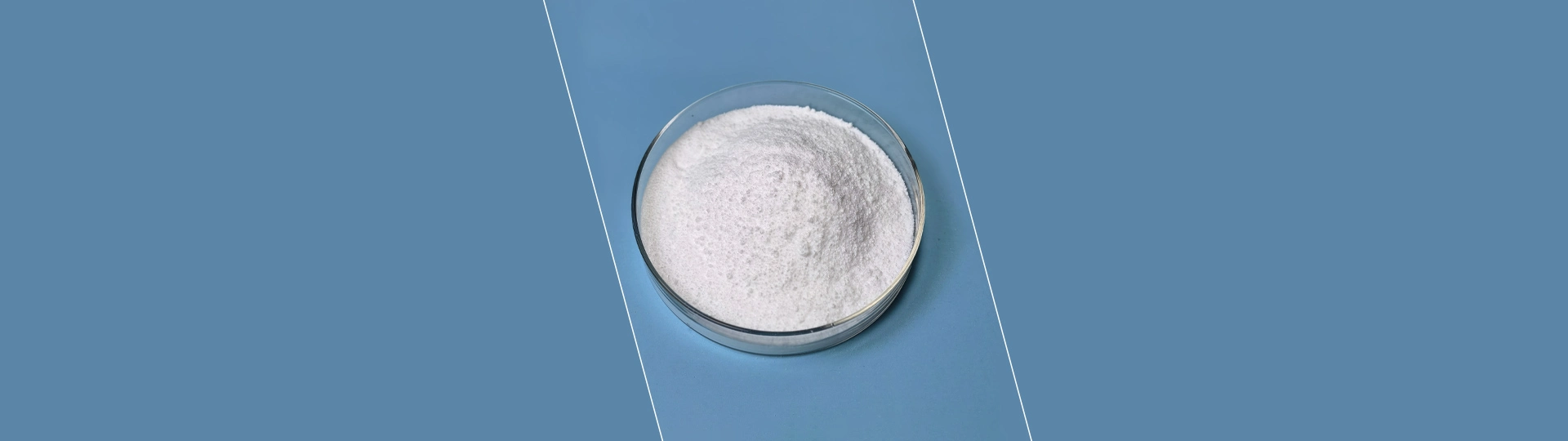

What is Fumed Silica: A Guide for Beginners

Fumed silica has been used in industrial settings since its invention in the early 1940s. The pyrogenic production technique, in which silicon tetrachloride is burned in an oxygen-hydrogen flame, gives it a diverse set of characteristics that distinguish it from other free-flowing additives such as titanium dioxide. It comprises finely dispersed amorphous silica dioxide, which has a reactive silanol group on its surface. Due to the absence of micropores, Fumed silica also has a space-filling particle structure and a high surface area.

How Is Fumed Silica Produced

Fumed silica is a type of synthetic amorphous silicon dioxide, produced by burning SiCl4 in an oxygen-rich atmosphere. It is made by flame pyrolysis of silicon tetrachloride or from quartz and vaporized in a 3000°C electric arc. The particles feature a surface area of 50–600 m2/g, a primary particle size of 5–50 nm, and a density of 160–190 kg/m3. The compound consists of amorphous silica fused into three-dimensional secondary particles. The chains and branches finally cluster into tertiary particles, providing the end product with low bulk density and high surface area.

Fumed Silica Applications

Fumed silica’s properties and porous structure make it an ideal additive for a wide range of applications. Some of the primary uses of fumed silica include:

- As a thickener or filler in paints, coatings, and adhesives

- In food and beverage products as an anticaking agent

- In pharmaceuticals and cosmetics as a bulking agent or stabilizer

- In the manufacture of semiconductors and optical fibers

- In the production of rubber and plastics

- As an extender in cement and concrete

- In the manufacture of ceramic tiles

Other applications and potential applications:

- Fumed silica promotes greater color uniformity.

- It can convert a liquid to a powder.

- It’s possible to create a powder containing up to 95% water using hydrophobic fumed silica.

- Flow aid to prevent caking.

- Thicken oil, resulting in clear liquid when the refractive index is matched.

- Enhance the viscosity of water in oil emulsions.

- Stabilize water in oil emulsions.

- Hydrophobic fumed silica can improve the SPF of sunscreen formulations.

- Suspend and prevent cumulation of powdered antiperspirant actives in roll-on deodorants and sprays.

- Can be used as a stabilizing and thickening agent in bleaching creams.

- Combined with quaternary ammonium compounds in hair rinses it improves the quality of hair.

- Improves the coverage and prevents settling in nail enamel formulations.

- Improves color dispersion and stability of lipstick formulas, extending their shelf life.

5 Key Fumed Silica Advantages And Properties

- Fumed silica has a high surface area and a porous structure, making it an ideal additive for many applications.

- Fumed Silica is safe to use and has low toxicity.

- Fumed Silica is environmentally friendly and does not contribute to global warming.

- Fumed Silica is non-corrosive and does not react with other chemicals.

- Fumed Silica is a versatile product that can help to improve the quality and performance of products in a number of industries.

10 Differences Between Fumed Silica and Fumed Alumina

Fumed silica and fumed alumina are both types of synthetic amorphous silicon dioxide. However, there are several key differences between these two products:

- Fumed alumina is a faster-acting product than fumed silica.

- Fumed alumina has a higher refractive index than fumed silica.

- Fumed alumina is stronger than fumed silica.

- Fumed silica is more affordable than fumed alumina.

- Fumed alumina has a higher melting point than fumed silica.

- Fumed silica is more porous than fumed alumina.

- Fumed silica is more hydrophilic than fumed alumina.

- Fumed silica generally has a higher surface area than fumed alumina.

- Fumed alumina is less versatile than fumed silica.

- Fumed silica is, at present, in broader industry use than fumed alumina.

10 Differences Between Fumed Silica And Silicon Dioxide

Although both are classified as free-flowing additives, there are a number of key differences between fumed silica and silicon dioxide:

- Fumed silica is a synthetic product, while silicon dioxide is natural.

- Fumed silica is an amorphous product, while silicon dioxide is a crystalline product.

- Fumed silica has a higher surface area and a porous structure, while silicon dioxide has a lower surface area and a less porous structure.

- Fumed silica is more refined than silicon dioxide.

- Fumed silica is more expensive than silicon dioxide.

- Fumed silica is more reactive than silicon dioxide.

- Fumed silica has a higher melting point than silicon dioxide.

- Fumed silica is less hydrophilic than silicon dioxide.

- Fumed silica has a higher refractive index than silicon dioxide.

- Fumed silica is more important than silicon dioxide in most industries.

If you have any questions about CE Chemicals Fumed silica, or if you would like to request a sample, please contact us. Our experts will be happy to assist you.